Master the art of the samurai with our premium Katana – the ultimate fusion of power, precision, and tradition! Handcrafted with high-carbon steel and razor-sharp edges, our authentic katanas deliver flawless balance and deadly performance. Loved by US martial artists, collectors, and enthusiasts, each sword is a masterpiece of Japanese craftsmanship. Whether for training, display, or appreciation, our katana is the #1 choice for those who demand excellence. Own a legendary blade today!

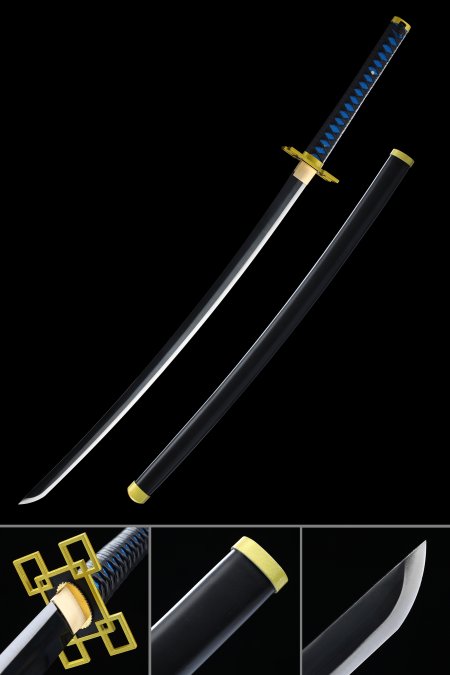

Katana SetManga Katana

This katana is amazing! Very well made, balanced, and looks great. Everything about it is awesome! I will be ordering more in the near future!

|

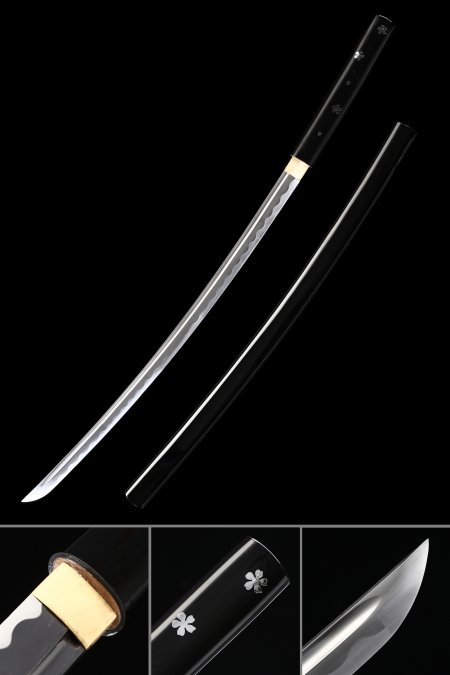

Handmade Bleach Kurosaki Ichigo Bankai Tensa Zangetsu Anime Katana Swords |

These katanas are beautiful, excellent customer service, and fast shipping.

|

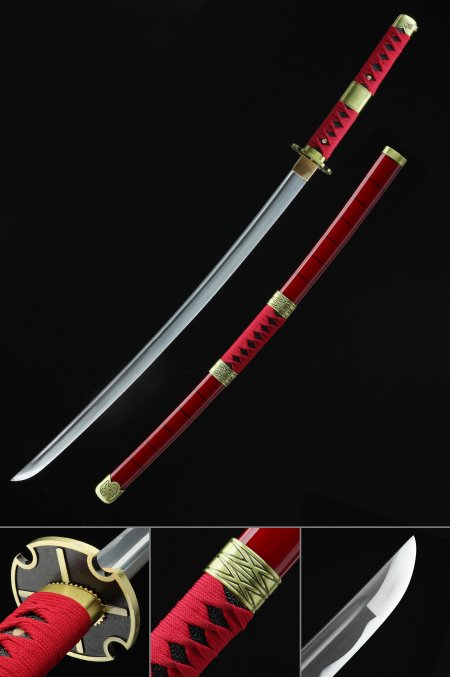

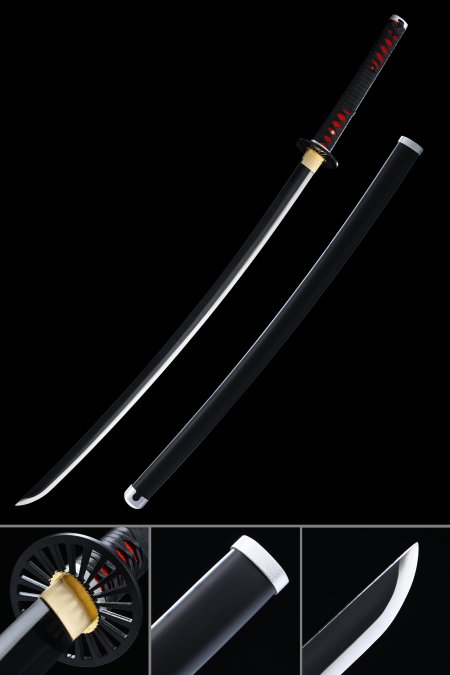

One Piece Roronoa Zoro Sandai Kitetsu Katana Samurai Sword Replica With Red Scabbard |

I love the sword thank you so much for the time and energy into making it💯💯

|

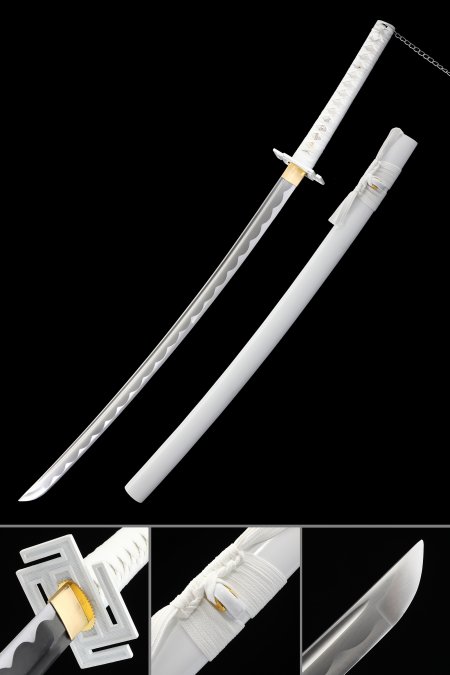

Handmade Hattori Hanzo Kill Bill O-ren's Shirasaya Katana Sword |

Im very pleased with the katana it is just as i hoped it would be i plan to have it on display withmy walking dead items

|

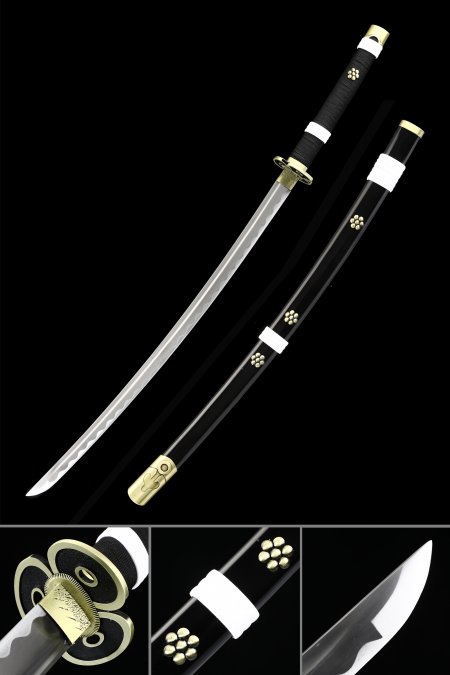

The Walking Dead Michonne's Katana, Zombie Slayer Katana Sword With Strap |

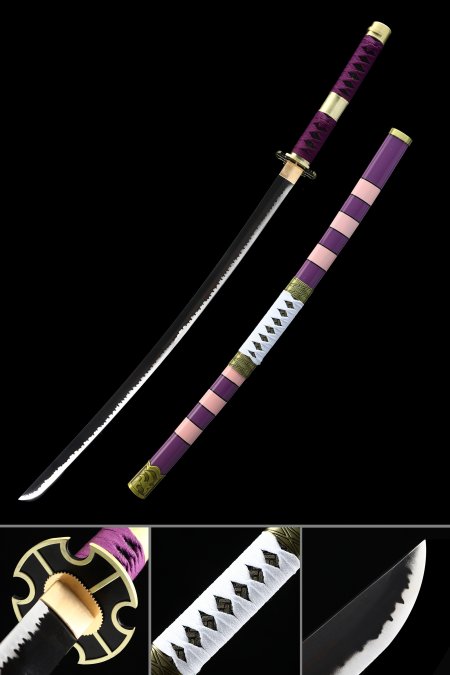

love the sword overall but i do notice different shades of purple on the top & bottom. aswell as a gold decor piece is loose. As with all my items i will just care for it closely, but it is loved!!

|

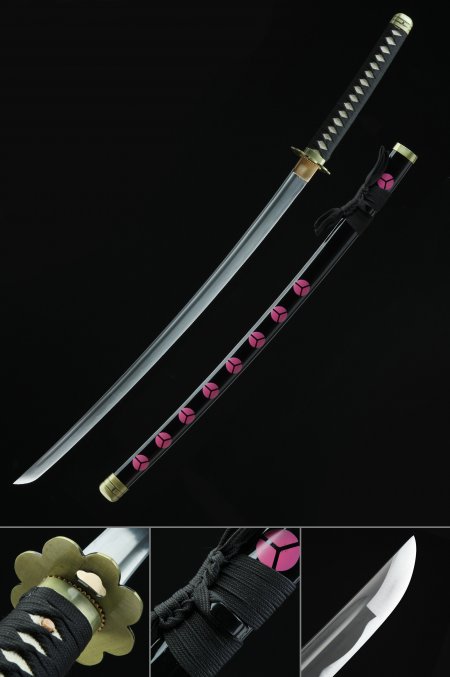

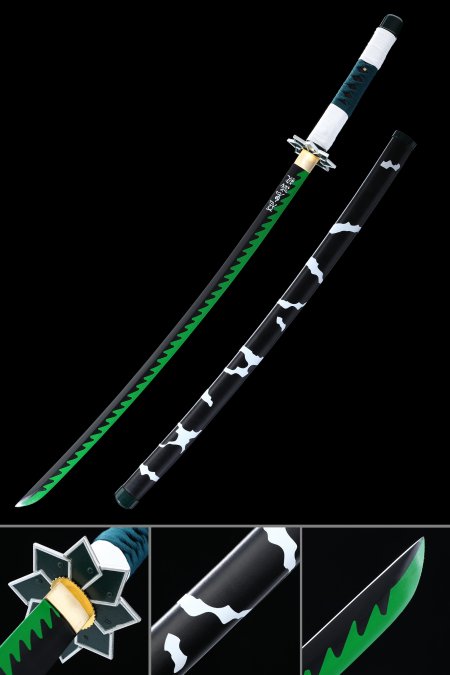

Yama Enma Sword, Roronoa Zoro Katana, Trafalgar D Water Law Anime Sword |

The sword came fast, its nice and sharp and I love how detailed it is

|

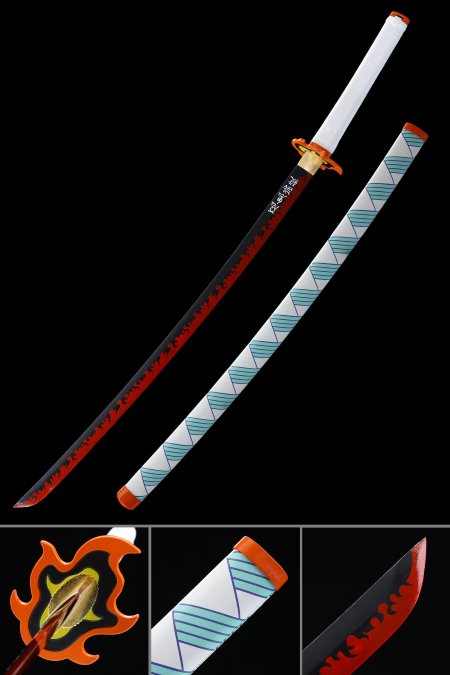

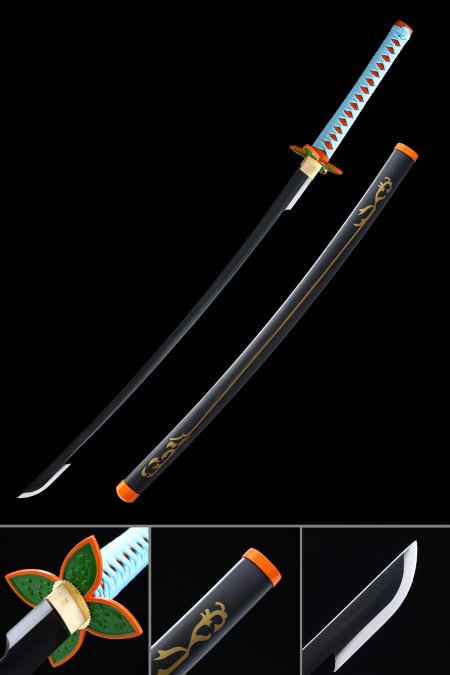

Zenitsu Agatsuma's Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

Got here very fast (within about 4-5 days). Looks awesome as a centerpiece on my wall. Has a very durable feel to it. Would purchase from here again in the future.

|

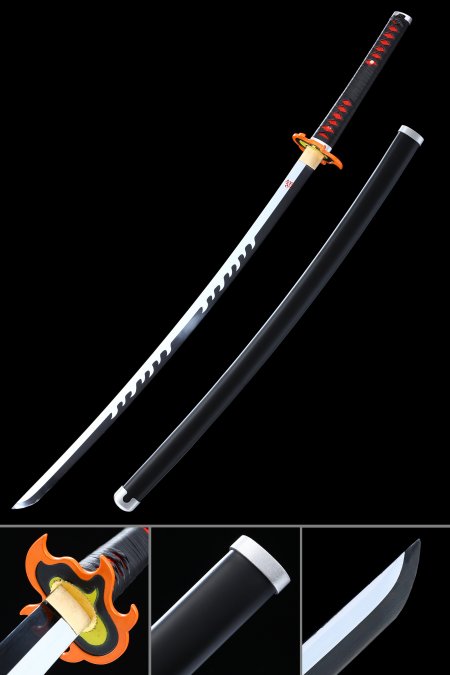

Kyojuro Rengoku's Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

The sword was actually very sturdy and good quality

|

Handmade Bleach Kurosaki Ichigo Bankai Tensa Zangetsu Anime Katana Swords |

Perfect katana to use to displaying or playing with. Very sharp, durable and bendable. Perfect handling and unsheathing is perfect.

|

One Piece Roronoa Zoro Sandai Kitetsu Katana Samurai Sword Replica With Red Scabbard |

Es una belleza estoy enamorado de este producto muchas gracias es excelente

|

Handmade Bleach Kurosaki Ichigo Bankai Tensa Zangetsu Anime Katana Swords |

This was a very nice katana, exceeding my expectations based on the cost. It was my daughter's favorite Christmas gift and a great replica of the Shinobu katana from Demon Slayer

|

Shinobu Kocho's Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

Husband loved it! Was a Christmas present and both of us were absolutely thrilled with the quality and how much it really looks like THE Wado Ichimonji. Will be purchasing from here again.

|

One Piece Roronoa Zoro Wado Ichimonji Real Katana Samurai Sword Replica With White Scabbard |

It is amazing!!! Came very quickly and is really just beautiful. My husband absolutely loves it, and we will be getting more in the future!

|

Kamado Tanjiro's Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

Amaazing quality 100% real my fiance loved it thank you❤️

|

Handmade Bleach Kurosaki Ichigo Bankai Tensa Zangetsu Anime Katana Swords |

I had to order a gift last minute (12/16) and was super nervous but Truekatana pulled through, was true to their advertising and delivered as promised. My gift arrived on 12/23 and it is exactly what I expected/ordered, perfect. Thank you! My only critique, to show fairness is that I didn't receive a shipping confirmation (adding to the super nervousness). Considering the whole experience I will still give 5 stars and order from them in the future.

|

Inosuke Hashibira's Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

Got this for my boyfriend for Christmas, and it is amazing! better quality than I imagined. I think I might be more obsessed than he is!

|

One Piece Roronoa Zoro Shusui Katana Samurai Sword Replica With Black Scabbard |

Some wax in the sheath making it a tad hard to sheathe the sword. Otherwise lovely blade. Thank you.

|

Yama Enma Sword, Roronoa Zoro Katana, Trafalgar D Water Law Anime Sword |

Good quality, pretty heavy, not too sharp. Definitely good for displaying. Definitely will get more from here, when I can

|

Kokushibo Sword, Demon Slayer Sword, Kimetsu No Yaiba Sword - Nichirin Sword |

The detail on the blade scabbard are incredible. I am disappointed with the lack of the chain from the anime at the end of the handle and lack of detail on the hilt.

|

Handmade Bleach Kurosaki Ichigo Bankai Tensa Zangetsu Anime Katana Swords |

Amazing as usual. Super fast shipping and great quality! Always willing to order again.

|

One Piece Roronoa Zoro Yubashiri Katana Samurai Sword Replica With Black Scabbard |

A katana is a japanese sword characterized by a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands.

The katana is generally defined as the standard-sized, moderately curved Japanese sword with a blade length greater than 23.86 inches. It is characterized by its distinctive appearance: a curved, slender, single-edged blade with a circular or squared guard and long grip to accommodate two hands.

Western historians have said that the katana was among the finest cutting weapons in world military history.

Having a regular cleaning routine in place is key to maintaining your katana.

You can purchase a traditional sword cleaning kit that will have everything you need. There are three steps: removing oil, polishing the blade, and oiling the blade.

Using a sheet of rice paper from the kit or soft cotton cloth, remove any oil that is still on the blade from the previous maintenance. Take the powder ball and tap it lightly against the blade about every two inches or so along its length. Take a fresh piece of rice paper and rub the powder over the blade to polish it. Do this until both sides of the blade have been polished and the powder completely removed. Take the bottle of oil and apply a few drops along the length of the blade on each side. Use a fresh piece of rice paper to spread the oil evenly on the blade.

The most iconic and well known of all the Samurai swords; the katana is distinguished by its long blade and handle that is made to accommodate two hands and strike from a large distance. It has a curved, slender, single-edged blade with a circular or squared guard. The katana has a set of dimensions that separate it from other samurai swords. A traditional katana will measure 3 to 4 feet in total length, with the hilt taking up one-fourth of the total and a characteristic curvature of more or less than 1 inch.

A full tang katana is the sword where the tang extends to almost the whole length of the handle, which makes the blade and the handle the same piece of metal. This gives to the sword certain rigidity and makes it a very solid piece to enjoy.

Full Tang katanas are handmade swords. They can be made of various stainless-steel types according to the Carbon Concentration. The forging is the essential part of the production because it allows the samurai sword to be solid and relatively light. Commonly, the piece of metal is repeatedly heated by fire and hammered while the metal is being folded. The mounting of the different parts is a very delicate operation that has its origins deep in the Japanese civilization. Samurai are used to cherish their Katanas as their trusted partners, and they handle them with love and care.

Clay tempered katana are swords made according to a particular process of blade reinforcement. During the forging, there are steps to go through involving several steps and some compounds mixture, used by the entire swords forger, yet each has its own formula. The compound mixture is none but Clay recipe that each forger has a secret ingredients list. Clay tempering is supposed to be an art more than a sword works. Clay tempered katanas are said to be more resistant and durable. Clay treatment must be operated by professionals to be efficient. Also, each steel type is supposed to be responsive to different clay compositions.

Traditionally, Carbon Steel is obtained by firing up a particular type of charcoal within a Clay Tub for approximately 72 hours. Iron powder should be added at determined amounts to associate appropriate quantity of Carbon. At the end, the obtained Steel is Stainless; its solidity depends on the amount of Carbon that associates to Iron. The steel obtained is referred to by four digits number which designates Carbon by the two first digits and the percentage of Carbon within the steel. Thus, 1045 Carbon steel refers to Carbon steel material that contains 0.45% Carbon fraction. It is called Medium Carbon Steel as well because that carbon concentration is the minimal required for the Steel to be used for industrial purposes; there are lower concentrations of carbon, but the materials are not suited for industrial use. 1045 Carbon Steel is suited for making katanas because it is cheaper than the other materials used for this industry. It is softer and easily forged. The proper application of the hardening techniques and the Clay treatment, certainly produce amazing steel that can be forged in real pieces of arts.

1060 Carbon Steel is a high carbon steel. The number 1060 refers to a material made of an alloy of Iron with a Carbon tenor of about 0.60%. Other elements can be found mixed to this alloy, but their tenors are not very significant. 1060 Carbon Steel Is harder than 1045 Carbon Steel; this property makes this steel harder to forge. The high Caron tenor makes the 1060 Steel more durable, but it is not high enough to compromise its pliability. The swords made of 1060 Carbon Steel keep their edges sharp longer and they are more expensive. It is the favorite steel material of famous swords companies.

1060 Carbon Steel katanas inherit the durability and the hardness of the steel material. 1060 Carbon Steel Katanas require more effort to produce. The edge is durable, and the sharpness lasts longer. It is more resistant to corrosion and oxidation and therefore requires less maintenance processing than the 1045 Katanas. Though, it is very important to clean the blade and polish it after every extensive use to ensure the durability and the sharpness, and to keep the edge healthy. 1060 Carbon Steel Katanas are expected to be heavier than those made of 1045 Carbon Steel, because of the steel properties. These Katanas create curves while being forged. This is the property of high and medium Carbon Steels: they keep a certain softness which makes them to develop ideal curves during the clay tempering processes and folding operation. The differential hardening and the folding operations, which are meant to harden the blade can increase the weight of the piece; this situation is handled by an aesthetically implanted blood groove that help eliminate the extra weight but keep the resulting spine from the differential Clay Tempering process.

1060 Carbon Steel Katanas have the medium rank between 1045 and 1095 Carbon Steel Katanas. It appears that they are appreciated for their durability, their hardness and for their affordable price if compared to properties. The easiness of forging reduces dramatically the price of the 11060 swords and makes them very popular.

1060 carbon steel katana is customizable from the forging to the mounting processes. You can chose the Hamon type, the sharpness of the edge, the hardening type and even the forging process. 1060 Carbon steel is hard steel but it is susceptible to hand forging, special press mechanical devices and to milling by dedicated machinery. Opting for 1060 Carbon Steel material is to choose low price material that can be forged into resistant and valuable pieces.

1095 Carbon steel is carbon steel that contains 0.95% of Carbon. Actually, it is called very high carbon steel. This carbon percentage results in hard steel, which is hardly forged by hands. The heat treatment must be conducted delicately because the carbon tends to leak at a certain temperature and if improperly heat treated.

?Heat treatment is to be operated very carefully because it is a delicate operation: improper treatment can result in loss of the carbon fraction and therefore the non-obtaining of the martensite, which can result in the loss of the whole material. The 1095 Carbon Steel comes to be softer than the Stainless Steel, yet it is easier to handle, durable, and more resistant. But among the Carbon Steels, 1095 is the hardest and perhaps the best choice for making swords intended to last longer while being roughly and frequently used.

The Carbon element makes the obtained steel relatively resistant to oxidation even if it has no chromium to be considered stainless. Although, the acquired durability which excels the durability of the Stainless Steel, makes Carbon Steel more preferred for making Swords.

1095 carbon steel katana inherits the hardness and the toughness of the Carbon Steel material. The Swords are intended to regular use and very frequent Dojo cuts. For outdoor displays and shows, 1095 Carbon Steel katanas are more suitable than the 1060 and 1045 Carbon steel Katanas; the last one is already preferred when it is about decorative use. The hardness of the Steel makes the forging process into sword a tough operation and increases the price value of the resulting piece, if handmade. This characteristic induces excellent durability for the 1095 Carbon steel Swords. The durability and the Edge Sharpness are reinforced by the Differential hardening process. It is important to notice that Clay tempered 1095 carbon steel katana are resistant to corrosion and are more resistant to oxidation; they are perhaps stainless. These swords are easier to sharpen and they do not need to have a thick layer of what the swordsmen call 'meat'; the edge keep its sharpness for long time.

The hardness of the 1095 Carbon Steel katana is inherited from the Steel material used for the forgery. Actually, forging Katanas fusing 1095 Carbon Steel appears to be harder than forging swords from others Carbon Steel types. Thus, the price of a 1095 Carbon Steel Katana tends to be higher.

Although 1095 Katanas are tougher than the others Carbon steel Swords they are still susceptible to abrasion and to corrosion if they are not properly cleaned and carefully maintained. Thus, applying cleaning process and using the recommended oil and tools to proceed may augments the durability of the edges and keep the 1095 Carbon Steel katanas properties for long time.

The toughness of the blade, which allows it to be the favorite choice for frequent functional use, may require particular pieces to mount on the blade to form the final Katana. Already, the Carbon steel type has imposed the forging process.

1095 Carbon Steel Katana are full tang katanas because of the hardness of the material and its resistance to shocks which require a tough handle mounted on a tang that is solid enough. Differential Clay Tempering results in a hardening the edge and keeping the spine softer, this operation may increase the durability of the edge and enhances the resistance to corrosion, therefore the edge will support the frequent dojo cut and outdoor display.