What distinguishes a short Japanese katana from a Chinese or Western short sword?

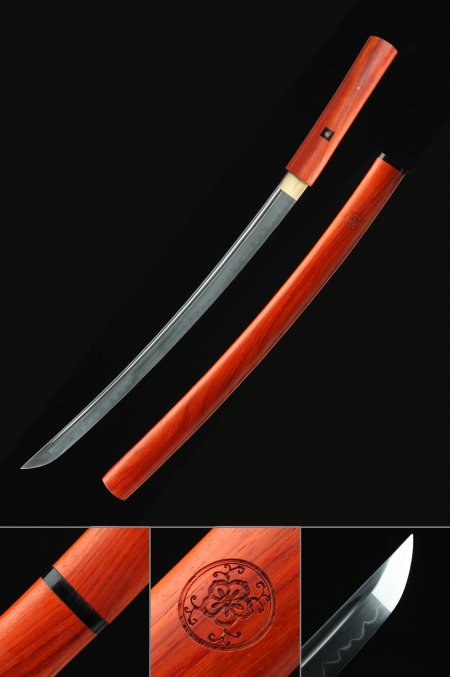

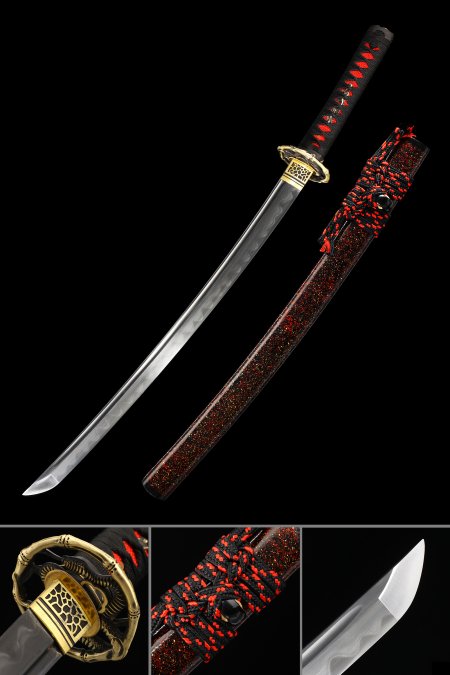

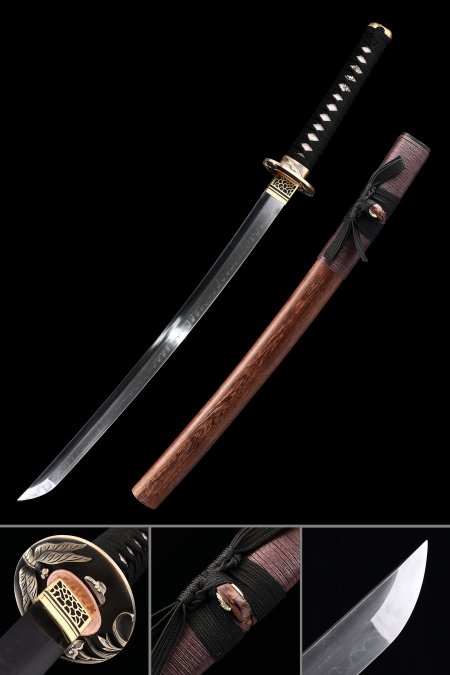

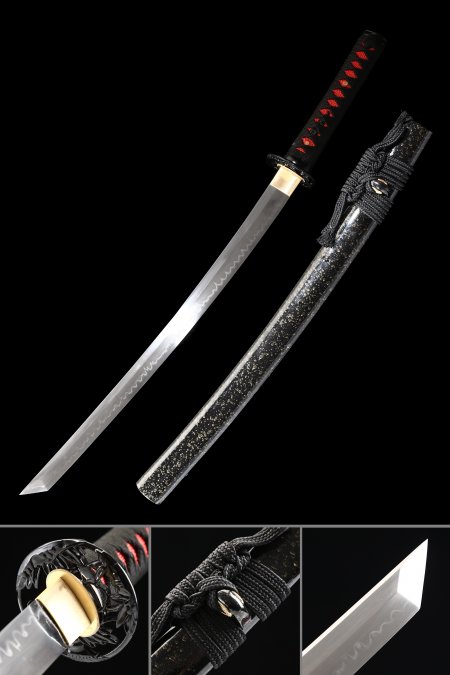

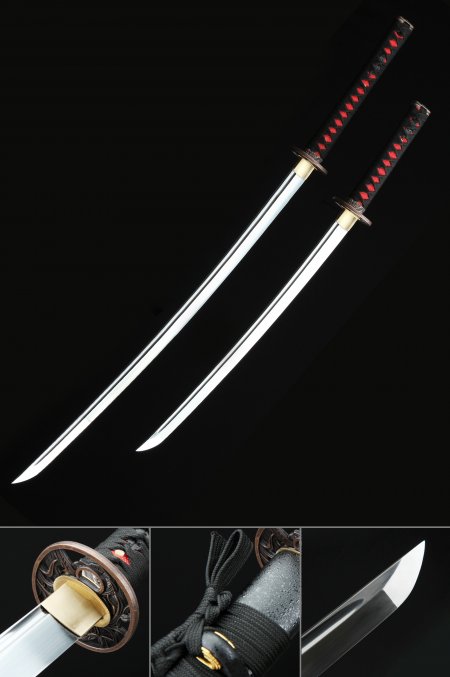

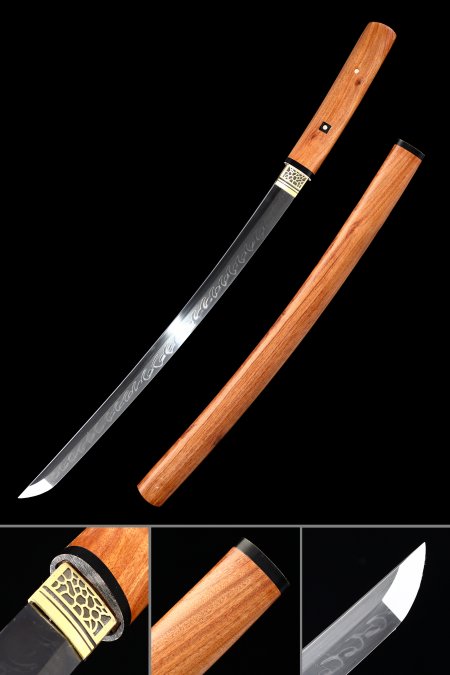

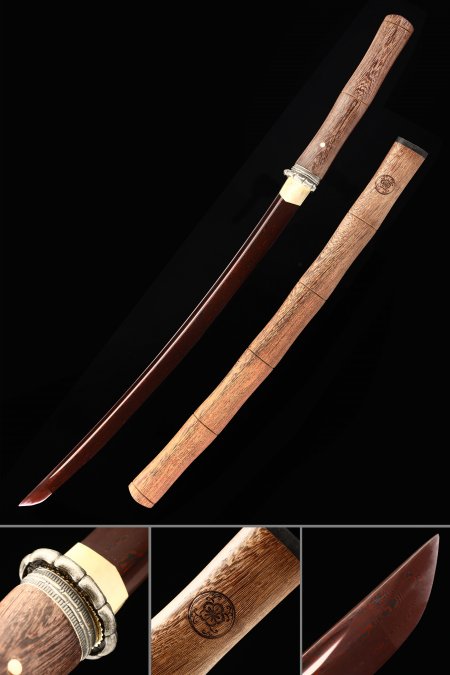

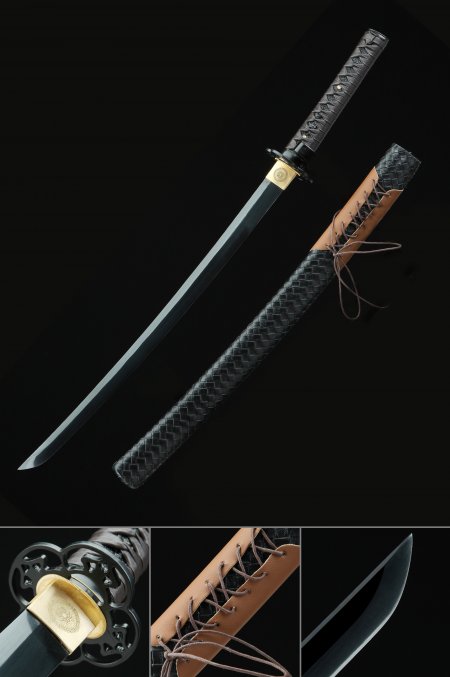

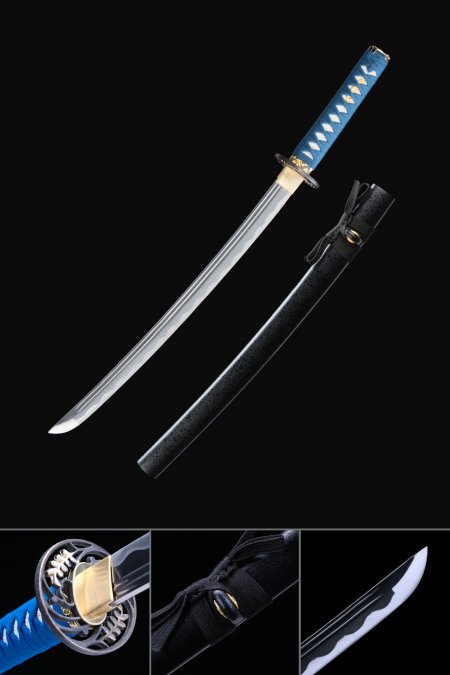

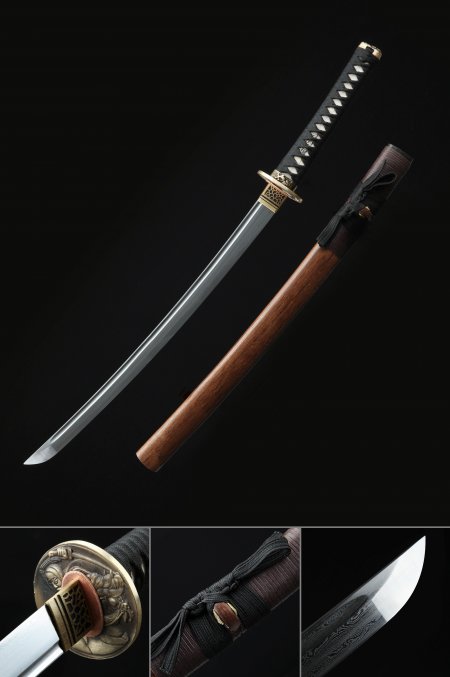

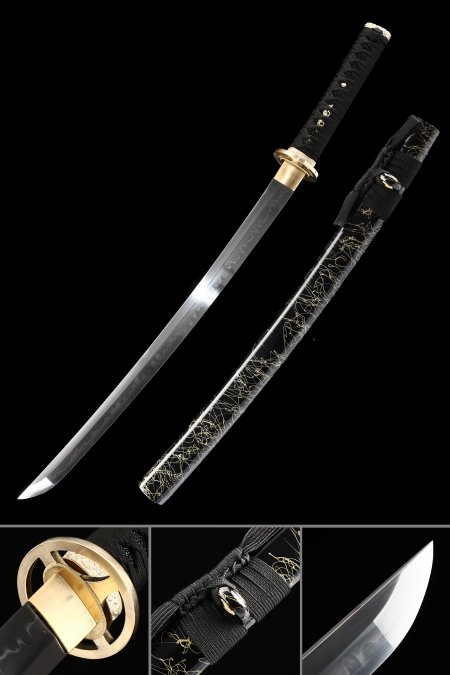

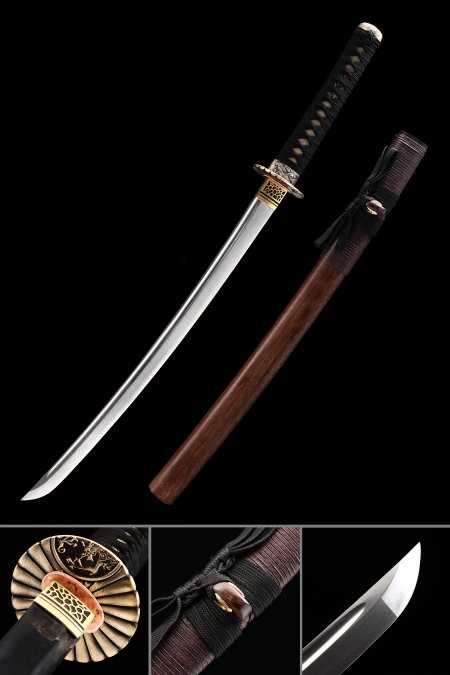

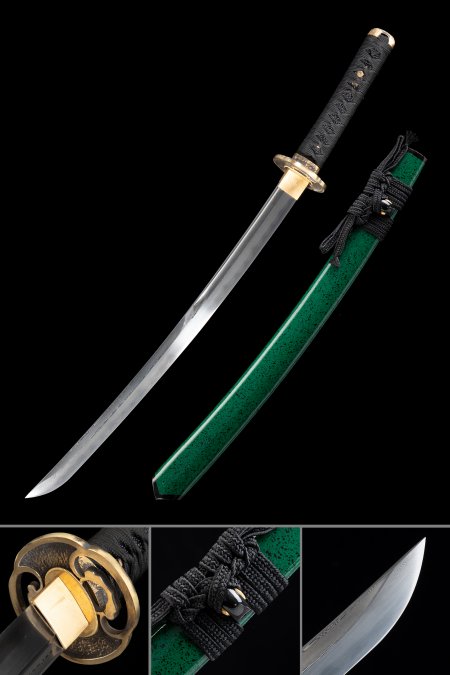

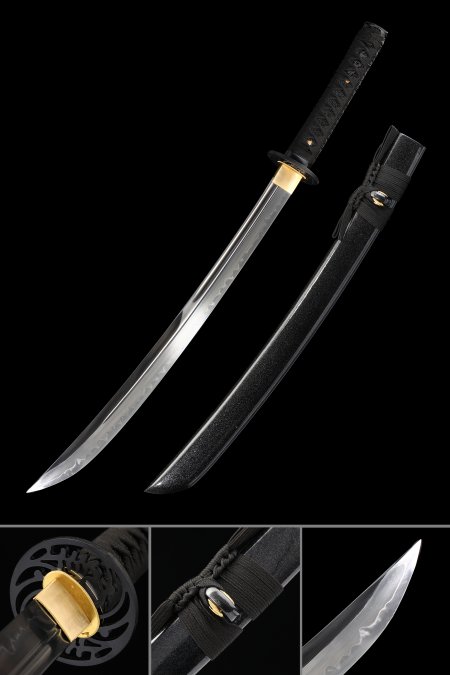

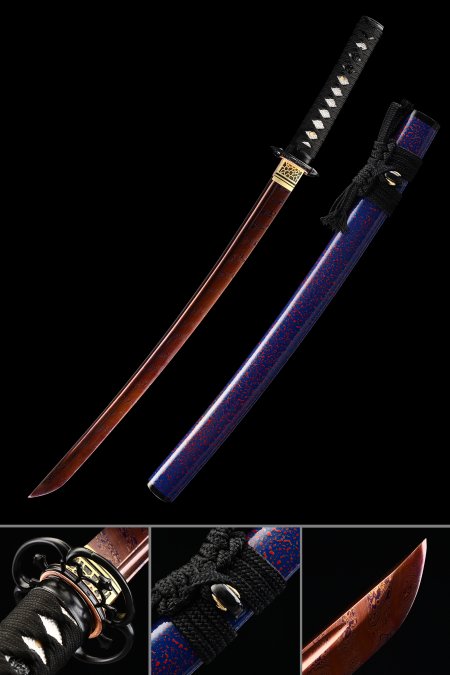

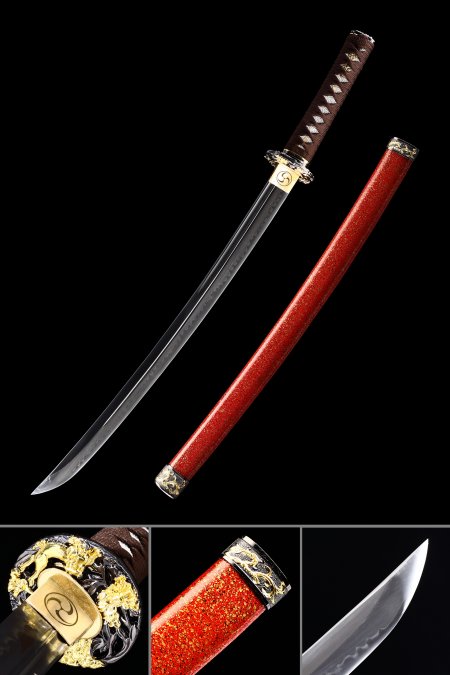

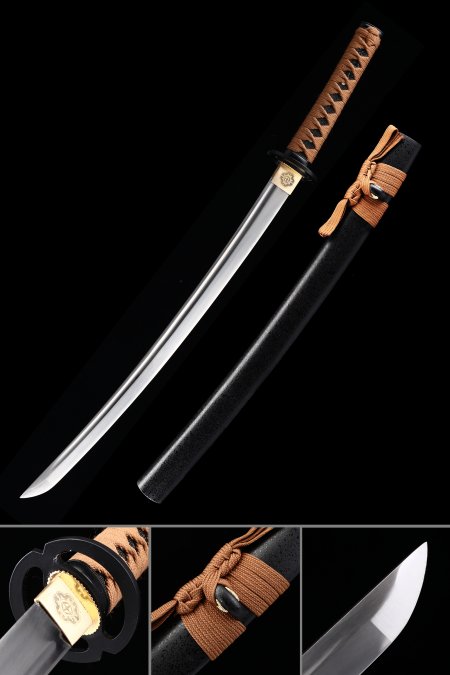

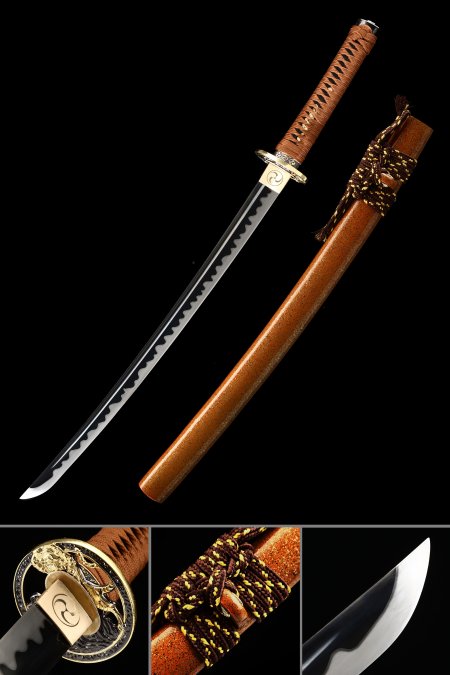

A short Japanese katana is distinguished from Chinese or Western short swords by the specific combination of blade geometry, steel treatment, and fitting tradition that defines the Japanese sword-making school. The curved single-edged blade with the Japanese kissaki tip geometry, the differential heat treatment that produces a hamon temper line, and the full fitting set of tsuba guard, ray-skin handle wrap, ito wrapping, and lacquered scabbard are all elements specific to the Japanese sword tradition and immediately distinguish a Japanese short katana from a Chinese dao or jian, a European short sword, or any other regional blade form. The hamon in particular is a uniquely Japanese element - the specific clay-tempering technique that produces it was developed within the Japanese sword-making tradition and is not found in the same form in any other blade-making tradition. For collectors who specifically want a Japanese-tradition short sword rather than a multi-cultural short blade collection, the short Japanese katana is the authentic representative of the Japanese side of the category.

What is a T10 clay-tempered short katana and why is it collectible?

A T10 clay-tempered short Japanese katana is a blade forged from T10 carbon steel - a premium grade with tight grain structure and controlled carbon content - and heat-treated using the clay tempering method that is the most traditional and technically demanding differential hardening technique in Japanese sword-making. In the clay tempering process, a thick layer of clay is applied to the blade spine before quenching, leaving the edge area uncovered or covered with a thinner clay layer. When the blade is quenched in water or oil, the clay-insulated spine cools slowly while the edge cools rapidly, producing a blade with a hard edge zone and a tougher spine zone. The boundary between these two zones is where the hamon forms: the wave-patterned visible line that indicates where the differential hardening took effect. On T10 steel, the hamon is typically well-defined and shows visible activity within the transition zone - nie, nioi, and other structural features that experienced collectors evaluate carefully. A T10 clay-tempered short katana with a well-defined hamon is the most technically accomplished configuration in the short Japanese katana category.

How should I evaluate a short Japanese katana before purchasing?

Evaluating a short Japanese katana involves examining several key construction and material indicators that distinguish a genuinely high-quality piece from a lower-grade alternative. Full-tang construction is the non-negotiable baseline: look for a mekugi retention pin visible through the handle, confirming the blade steel runs through the complete handle rather than tapering to a stub. Blade steel grade is the second critical factor: high-carbon steel grades like T10, Manganese Steel, 1045, or Damascus steel are appropriate for a quality collectible, while stainless steel indicates a decorative rather than craft-quality piece. For T10 pieces, a visible hamon under lighting confirms proper differential heat treatment. Handle wrapping quality is the third area: tight, consistent ito wrapping with no gaps or loose sections indicates careful construction throughout. Tsuba guard fit should be flush without wobbling or play. The scabbard should seat the blade securely without rattling, which confirms the habaki collar is properly fitted. Pieces that meet all these criteria are built to the construction standards appropriate to serious Japanese sword collecting.

How do I care for a short Japanese katana sword over time?

Long-term care for a short Japanese katana requires the same routine as any high-carbon steel Japanese blade, applied consistently after each handling session. After handling, wipe the full blade surface with a soft lint-free cloth to remove fingerprints and moisture. Apply a thin coat of camellia oil or mineral oil along the full blade surface using a separate cloth, then buff away excess until only a barely-visible film remains. This oil coating is the primary protection against oxidation and should be maintained as a regular habit rather than an occasional intervention. Check the habaki fit at the scabbard mouth periodically - a habaki that has loosened can allow the blade to shift in the scabbard, creating wear on the blade edge. Inspect the mekugi retention pin periodically as well, as temperature and humidity changes can cause the handle wood to expand and contract, potentially loosening the pin. For the lacquered scabbard, wipe with a dry soft cloth to remove dust and avoid prolonged contact with moisture. Store in a stable-temperature, low-humidity room rather than in a garage or basement where temperature swings are common.