Discover the exquisite beauty and craftsmanship of the Hamon Katana, where tradition meets artistry in every blade. Our Hamon Katanas are meticulously crafted to showcase the stunning hamon, a unique temper line that reflects the skill and dedication of master swordsmiths. Perfect for collectors and martial arts enthusiasts, these katanas offer a tangible connection to the rich heritage of the samurai. Elevate your collection with a Hamon Katana, a masterpiece that embodies the perfect blend of form and function. Experience the elegance and precision of this iconic sword, and let the Hamon Katana bring the spirit of the samurai into your life.

Honest feedback: My first ever katana. Beautiful craftsmanship. Does look exactly like the image online, and an intense feeling of caution and anxiety occurs when I unsheathe the blade. Hilarious, but highly important instruction/liability manual......DO NOT LICK THE BLADE. DO NOT CHOP VEGETABLES WITH THE BLADE. I can only image some of the cases.

|

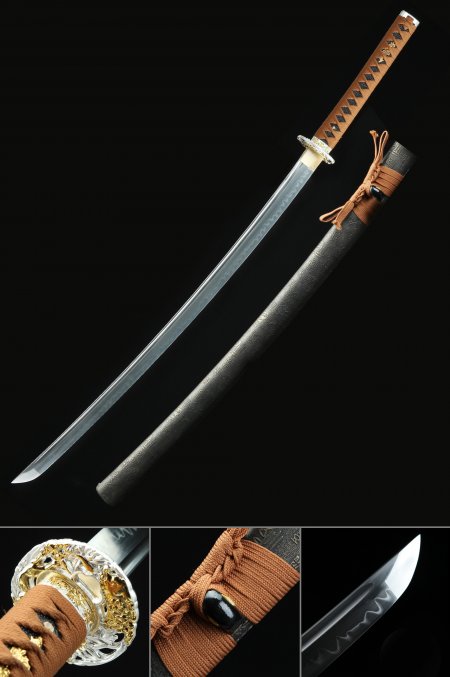

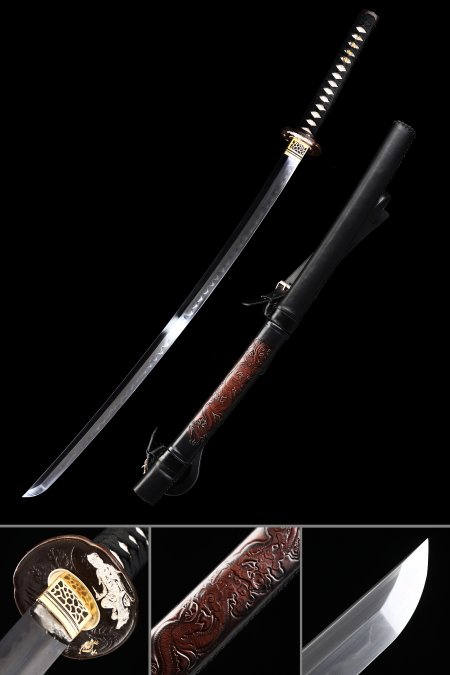

Handmade Japanese Katana Sword T10 Carbon Steel With Black Scabbard |

Love this sword. It was exactly what I was hoping for. I will be buying again.

|

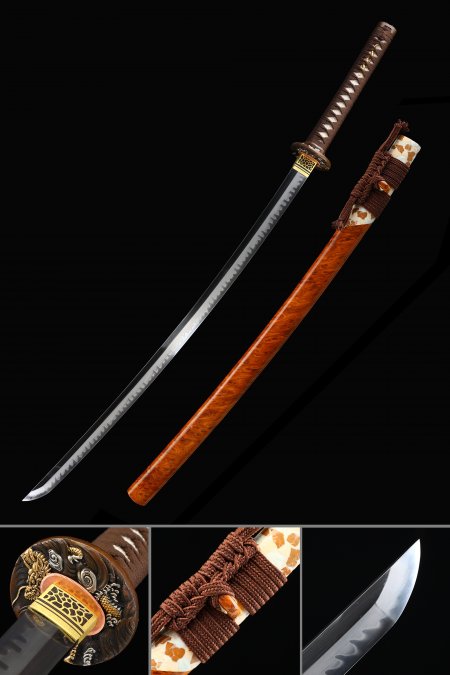

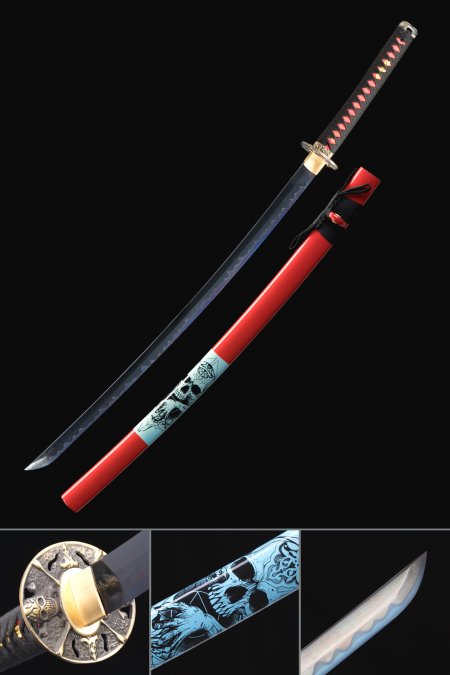

Handmade Japanese Sword T10 Folded Clay Tempered Steel With Red Scabbard |

Amazing condition not to mention blade already sharp enough to cut. Amazing handmade katana

|

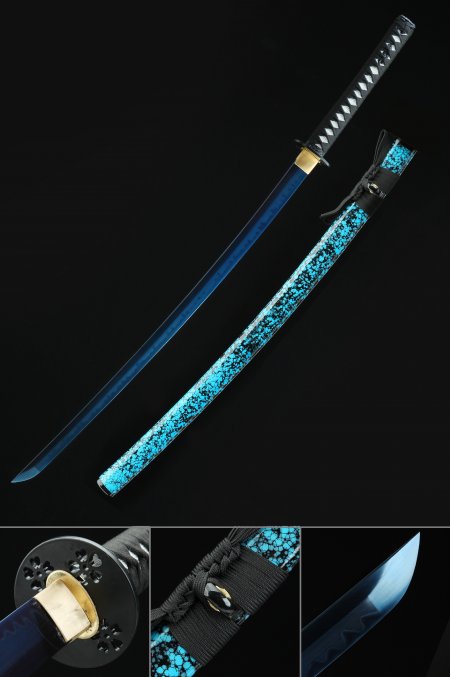

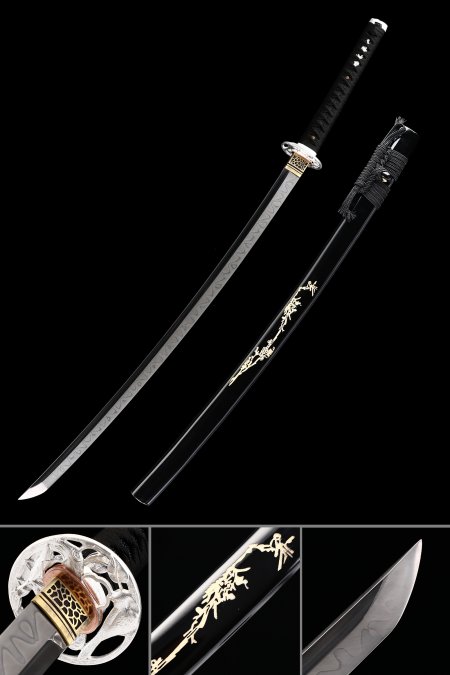

Handmade Japanese Samurai Sword With Blue Blade And Scabbard |

Took 6 days for my katana to arrive. Very happy with the fast shipping and packaging. My first ever sword, very grateful for this purchase won’t be my last buy.

|

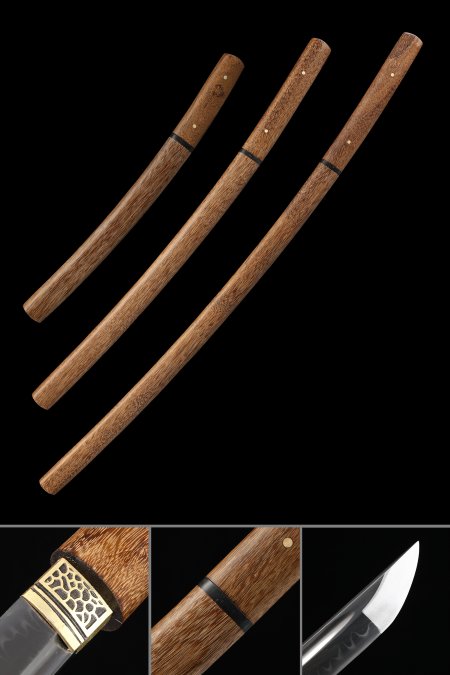

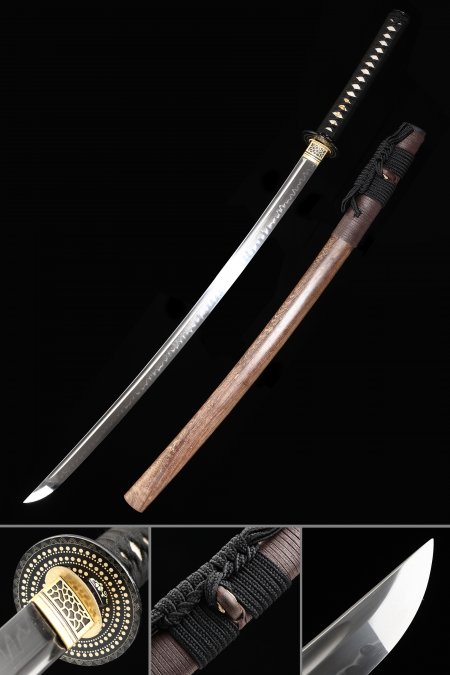

Handmade Japanese Shirasaya Katana Sword T10 Carbon Steel Real Hamon Without Tsuba |

The blade itself is beautiful And it arrived pretty quick. The fittings feel solid, and the overall aesthetic is exactly what I was looking for. However, the main issue is with the scabbard. Unfortunately, it doesn’t fit properly; the sword shakes inside, and if pointed downward, it falls out on its own. With that said if the saya had been properly fitted, this would have been nearly perfect.

|

Japanese Katana Sword T10 Folded Clay Tempered Steel With Black Scabbard |

Absolutely beautiful work of art! I’m so grateful to have stumbled upon this website. The katana is flawless in every aspect; you won’t be disappointed with your purchase.

|

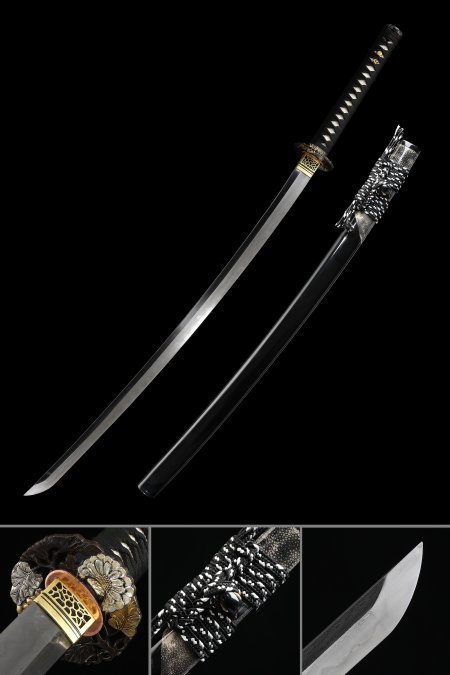

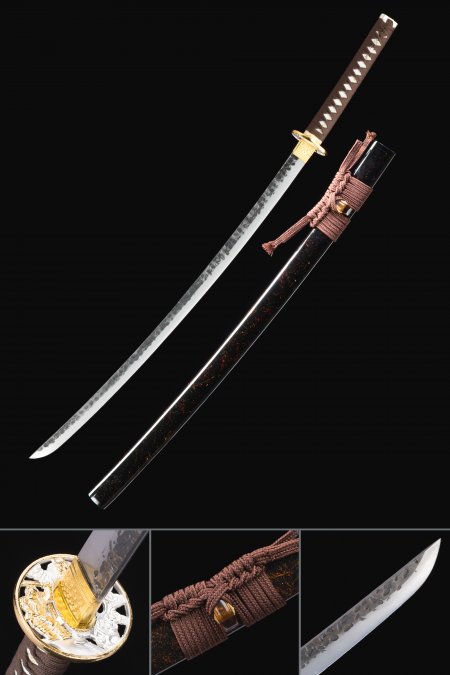

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel Real Hamon |

The katana arrived in 7 days. It is a beautiful blade and cuts smoothly and precisely.

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel With Silk Thread Scabbard |

The more I order from this place the more I love it! Everything is great quality really cool designs and pretty dang affordable if you ask me!

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel With White Scabbard |

It’s cool looking sword but realizing that’s it’s really bright pink makes me look gay asf so imma buy a different looking blade that has a better sheathe

|

Handmade Japanese Katana T10 Carbon Steel Clay Tempered With Pink Scabbard |

I was happy with Katana of purchase. t10 steel is a little heavy, but i can adjust.It is balance the blade very sharp. the blue design of sheath lovely. I didn't want it for decoration ,but battle ready situations.one thing i didn't recieved my certification of authenticity,I need my certification please. I will be purchasing a better Katana in the near future. I know I bought ar

bottom line entry level katana money was a factor. your customerr

Thank you

|

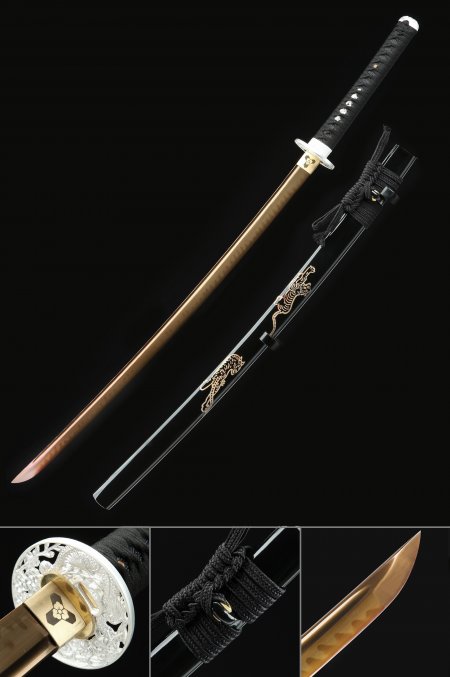

Handmade Japanese Samurai Sword Real Hamon With Blue Scabbard And Handle |

Love the Look of it online, but unfortunately the Dragon Carving is not as prominent as shown on the website. I’m not sure if this is on purpose or not but it seems that the lacquer/ varnish was over done and it covered the dragon carving to the point that it makes it almost invisible/ not easily seen.

Other than that I think that the Sword is amazing the Handle and the Tsuba are fitted great, I do wish that the Tsuba had a dragon design instead to match the Saya (sheath) but it’s sharp and feels really good in your hands.

If you want to buy it I’d double check regarding the Saya (Sheath) dragon carving and if it’s supposed to be dark like that or not.

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel Real Hamon |

So this was a good blade for the price. The sayia is loose but gorilla glue couldn't fix. As for the rest of the sword.

Hamon line isn't a real hammon for T10, but it is there'ish. It will cut but it being dojo ready without a bit of maintenance, it'll get there.

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel With Black Scabbard |

I wish I had a picture to show how beautiful this katana is. I spent more on this one and the quality difference was immediately apparent when I pulled it from the Saya. The hamon is beautifully crafted and the blade is mirror polished with minimal scratches.The curve of the blade is extreme and awesome. It feels incredible and nimble in my hands. It is so far my centerpiece of my collection and although I know it would cut beautifully ,I don't want to damage this artwork. Ok with that being said the Saya was a disappointment, all the components of the Saya are great however the seam of one side was obviously apparent and had very rough edges along the seam almost sharp and the fit of the Saya is very tight which I'm not sure is a bad thing as long as it holds together. I'm very happy with quality and craftsmanship of this katana so I'm ok with the flaws in the saya but a little surprised it wasn't caught before shipping.

|

High-performance Japanese Katana T10 Folded Clay Tempered Steel |

I love the sword it’s awesome and sharp well made

|

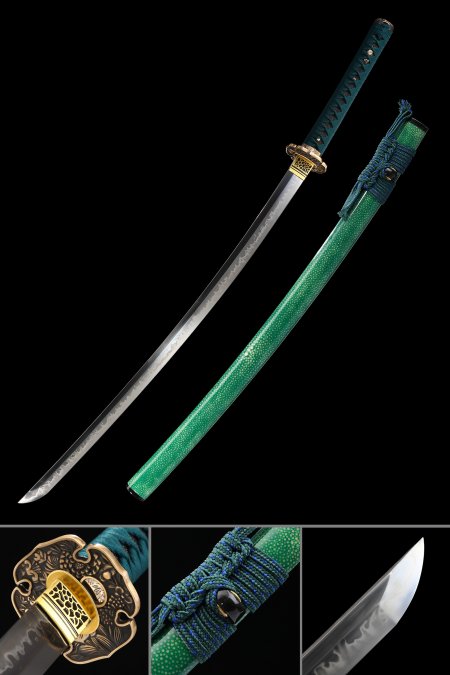

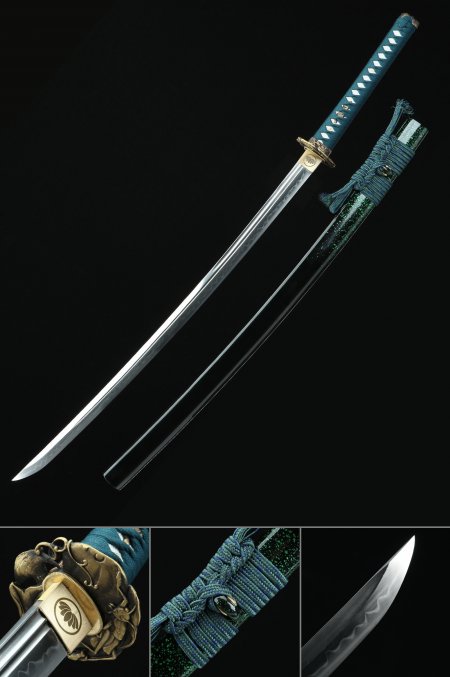

Handmade Japanese Katana Sword T10 Carbon Steel With Green Scabbard |

Place and recieved my order only to see the price has been reduced 30%...not happy that the discount wasn't applied to my order.

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel Real Hamon |

loved it had to order me a tachi to complete the set😍

|

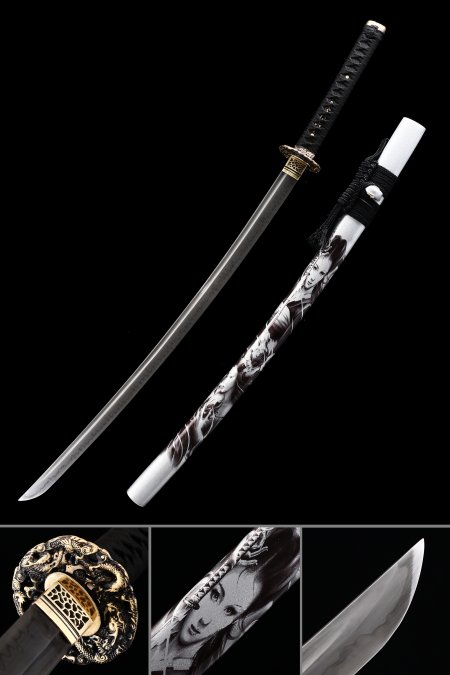

Handmade Japanese Katana Sword T10 Carbon Steel Real Hamon With White Scabbard |

I am very pleased with my purchase from this website. This actually my first time buying from here so I was very excited. The weight of the blade is excellent. It is sharp, so be careful handling this beautiful weapon.

I will be purchasing more in the future🔥👍🏽

Sincerely, SHOTTAS

|

Handmade Japanese Katana Sword T10 Folded Clay Tempered Steel Real Hamon |

I have purchased several Katana swords from Trukatana and my recent purchase is like the rest, totally AWESOME!!! The swordsmiths there understand what the word craftmanship really means!!! Totally satisfied!! Razor Sharp edge!! Would totally recommend!!

|

Short Katana, Handmade Wakizashi Sword T10 Folded Clay Tempered Steel With Flower Tsuba |

The sword is a darker blue than it looks and so is the scabbard however. The scabbard is about the color of the sword in the photo and the sword is very dark. Almost black. Both look very nice though. Sword is straight and it is sharp. Pretty decent balance. I'd say for the price you really won't beat it. Pretty fast shipping as well. Believe I got it in about 11 days. I'm not gonna say there aren't better but for a first sword or practice sword at this price I don't see you getting anything better. Metal seams to hold its edge good but I haven't done enough testing yet for that.

|

Handmade Japanese Samurai Sword With Blue Blade And Scabbard |

Loves the katana currently have it displayed above my desk and love how it looks. Came in with a oily substance in the blade but nothing a microfibre rag can’t get off. Would recommend and will be buying from this company in the future.

|

Handmade Japanese Katana T10 Carbon Steel With Rose Gold Blade |